Ensuring safe environments in pharmaceutical production

Protecting health, ensuring safety, and enhancing productivity with cutting-edge industrial hygiene solutions.

At Gasmet, we understand the critical importance of maintaining safe environments in the pharmaceutical industry. Our advanced gas analysis solutions are designed to help you monitor hazardous gases, ensuring the safety and well-being of your employees and compliance with industry regulations.

Why industrial hygiene is critical in pharmaceuticals

In the pharmaceutical industry, maintaining a safe and hygienic environment is paramount. The presence of hazardous gases such as Ethylene Oxide (EO), Acetonitrile (ACN), Acetic Acid, Dichloromethane (Methylene chloride), Hydrogen peroxide, Toluene, Ethyl Acetate, Heptane and Dichloroacetic Acid in sterilization and chemical processes poses significant risks. Effective gas monitoring is essential to protect workers from exposure to these toxic substances.

At Gamet, we provide industry-leading gas analysis solutions that help you identify, monitor, and mitigate these risks. Our technology is trusted by major pharmaceutical companies to maintain safe working environments, ensuring compliance with stringent safety regulations.

Gas analysis solutions for pharmaceutical safety

At Gasmet, we understand that each pharmaceutical environment is unique, requiring tailored solutions to address specific industrial hygiene needs. Here’s how we can help:

Real-time gas monitoring solutions

Continuous monitoring of hazardous gases like Ethylene Oxide (EO) and Acetonitrile (ACN) is crucial for ensuring workplace safety and preventing process failures. Our systems, trusted by established companies, provide real-time data to help you respond quickly to any potential exposure risks without compromising product integrity or worker safety.

Air quality assessments

Comprehensive air quality assessments, which identify potential risks and ensure a safe working environment, are made possible with state-of-the-art equipment like the GT5000 Terra. Companies rely on our technology to monitor various chemicals in their research facilities, enabling effective incident response and maintaining safety standards.

Regulatory compliance consulting

Navigating the complex regulatory landscape can be challenging. Our expert team provides guidance to help your organization comply with all relevant industrial hygiene regulations to avoid (penalties,) product recalls and compromised patient safety. For instance, we’ve helped companies ensure compliance with NIOSH guidelines for hazardous drug exposure.

Process efficiency

Monitoring and analyzing gas emissions can help to identify leaks and point out inefficiencies in manufacturing processes leading to improved production quality, consistency and saving costs. The gas analysis process can be integrated to existing workflows without disrupting production schedules or throughput.

Advanced gas detection technology

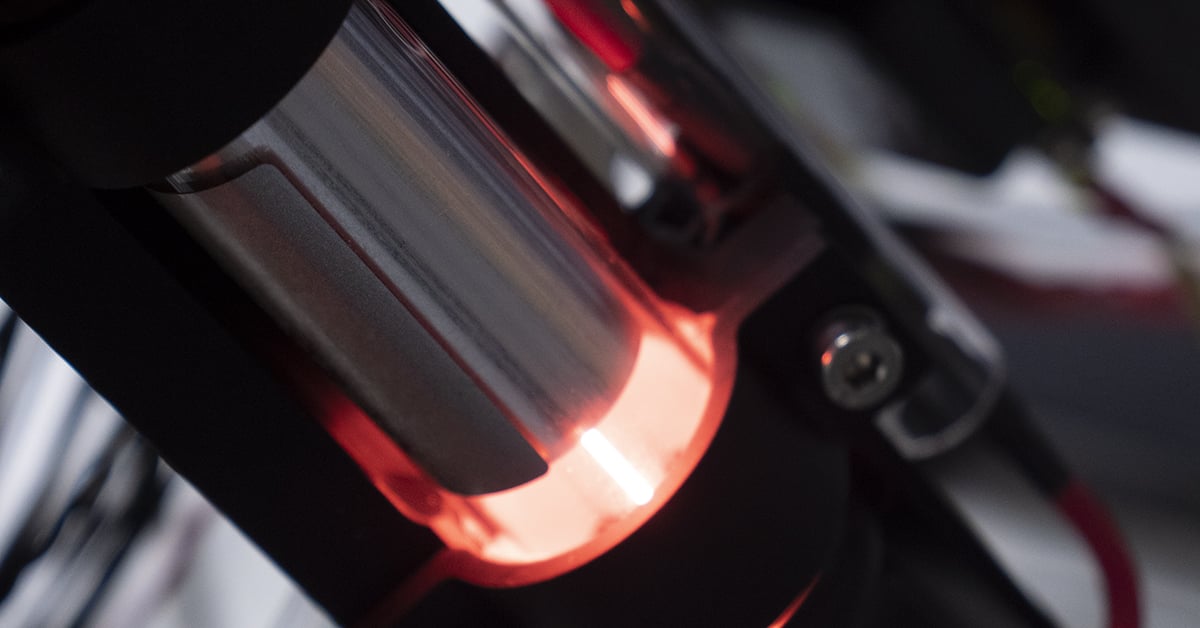

We utilize FTIR technology to provide accurate and reliable detection of a wide range of gases. The spectrometer measures all the IR wavelengths simultaneously and produces a full spectrum. Up to 50 gases are measured and interferences are automatically resolved.

Click below to attend a webinar to learn more about FTIR technology for gas analysis

Contact our experts

Are you contemplating if our solution works for your specific needs? Or do just want to know more or get a direct quotation for GT5000 Terra? Drop your details in the form and we will get back to you ASAP.

You can also sign-up to Gasmet's newsletter to hear what is happening in the world of health & safety gas analysis.

Related cases and articles

- Waste anesthetic gas analysis improves health care environment across US southwest

- Confined Space Entry – 4 main causes of serious accidents

- Benefits of Using Portable and Specific Gas Analyzers

- Train derailment prompts contaminated land investigation

- Analyzer underpins growth of container inspection company

- FTIR gas analyzers support management of fire at UK waste facility

- Gas analyzer builds complete picture of contamination

- FTIR meets Fire Testing needs for toxic gas analysis